Businesses and original equipment manufacturers (OEMs): when the time comes to report and monitor emissions for the Environmental Protection Agency (EPA), you’ve likely heard about five-gas analyzers.

These helpful machines are key in monitoring the greenhouse gas output of everything from automobiles to motorcycles to chainsaws and leaf blowers. If you lapse on monitoring your emissions output to the EPA, you’ll face steep fines and heavy penalties.

As such, knowing which gas analyzers are helpful is key for making your manufacturing and business operation more efficient, staying in compliance with federal regulations, and avoiding the wrath of the EPA.

Our scientists and engineers compiled this handy article about five-gas analyzers to help you better prepare for emissions monitoring and reporting for your operation. We hope you enjoy it.

In this article, we’ll cover:

- The purpose of five-gas analyzers

- What five-gas analyzers can do

- How these handy tools work

- The five types of gasses that a five-gas analyzer can monitor

- Three reasons why five gas analyzers are helpful

- Three categories of five-gas analyzers

The 5 gases that a 5 gas analyzer reads

| 1. Carbon monoxide (CO) 2. Carbon dioxide (CO₂) 3. Oxygen (O₂) 4. Hydrocarbons (HC) 5. Nitrogen oxides (NOx) |

The purpose of a 5 gas analyzer

A five-gas analyzer is a device that measures emissions from various engines. Five-gas analyzers can test emissions from equipment such as:

- Automobiles

- Marine vessels

- Heavy-duty, off-highway equipment

- Motorcycles and ATVs

- Power equipment (like lawnmowers, leaf blowers, and chainsaws)

- Equipment using small gasoline engines (like portable generators)

By analyzing an exhaust’s gas composition, 5 gas analyzers can provide valuable information for creating a more efficient, high-performing engine. Plus, 5 gas analyzers help ensure the equipment operations that produce fewer greenhouse gas emissions (GHG) that are safer for public use.

A 5-gas analyzer is a key component for ensuring vehicles adhere to emissions standards and regulations. With a 5-gas analyzer, operators can help detect and quantify pollutant levels. The data gleaned can help operators diagnose engine issues needing fixing.

The ultimate purpose of a five-gas analyzer is to improve vehicle efficiency and maximize performance while simultaneously reducing environmental pollution and increasing safety.

Uses of a 5 gas analyzer

So, what functions does a 5-gas analyzer serve?

A 5-gas analyzer can be used by auto and combustion engine experts for the following purposes:

- Dynamic road testing

- Fuel and emission diagnostics

- Carburetor balance checks

- Catalytic converter evaluations

- Monitoring, reporting, and verifying smog-causing emissions

- Leak detection and repairs (LDAR)

- Engine recalibration and positive crankcase ventilation system checks

- Optimizing fuel mixtures and measuring key automotive metrics like revolutions per minute (RPM)

This list is not all-inclusive, so if you doubt whether a five-gas analyzer can support your operation, don’t hesitate to reach out to an emissions verification specialist. They can determine whether a five-gas analyzer is best for your particular project.

How an exhaust gas analyzer works (6 steps)

An exhaust gas analyzer works by drawing in and measuring gas through the following seven steps:

- The analyzer draws exhaust gas from the engine exhaust tailpipe through a stainless steel probe.

- The probe attaches via an alligator or crocodile clip (depending on the analyzer) so the operator can insert the probe into the tip of the exhaust pipe.

- High-temperature silicone tubing material delivers the gas through the components and into the gas analyzer.

- The gas temperature and dew point changes. Condensation occurs, and a water trap traps the condensation water, so the water doesn’t reach or damage the gas analyzer (or you can utilize our filterless system that eliminates the need to review filters).

- The gas continues through the water trap and through the nitrogen oxide filter which filters acidic gas components.

- Then, gas enters the gas analyzer at room temperature. Voila! The gas is ready for gas sensor analysis, and the analyzer displays the detected gas concentration to the operator.

In summary, the exhaust gas analyzer takes in a sample of gas and siphons it off to be analyzed by an operator for further use.

Types of gases that a 5-gas analyzer analyzes

As its namesake alludes to, a five-gas analyzer analyzes five types of gas:

- Carbon monoxide (CO): an odorless gas that’s produced when fuel hasn’t completed combustion. High levels of CO can create a malfunctioning fuel system and errors with a vehicle’s air-to-fuel ratio.

- Hydrocarbons (HC): a gas that derives from unburned fuel or engine oil. Hydrocarbons are key to smog and can cause health issues. High HC levels in exhaust gases suggest issues like misfires, faulty ignition systems, and worn components.

- Oxygen (O₂): Engines that operate with a great deal of oxygen levels can cause damage to engine parts. For example, lean-burn — when fuel burns with more air and oxygen in an internal combustion engine than is warranted — can lead to emissions high in nitrogen oxides.

- Carbon dioxide (CO₂): is a byproduct of complete combustion. High CO₂ levels can be a double-edged sword. On the one hand, the presence of CO₂ can mean an efficient combustion process has occurred. On the other hand, CO₂ is a greenhouse gas that is harmful for our environment and can contribute to global warming.

- Nitrogen oxides (NOx): are produced during high-temperature combustion processes and can lead to smog, acid rain, and respiratory issues. High NOx emissions may mean problems with an exhaust gas recirculation (EGR) system.

We’ll explore why these five gases are important to analyze in the next section.

Key reasons why a 5-gas analyzer is useful

While five-gas analyzers can help with a variety of industry-specific processes, a gas analyzer is often used for the following reasons:

- Diagnosing engine problems

- Ensuring better engine performance

- Safeguarding occupational safety

- Helping companies ensure that their combustion engines adhere to emissions regulations administered by federal and local authorities

3 categories of engine exhaust gas analyzers

Gas analyzers also come in three distinctive styles, each of which is designed to meet specific needs. The three main types of engine exhaust gas analyzers include:

- Professional exhaust gas analyzers: These analyzers tend to be larger and more expensive than other gas analyzers. You’ll find these gas analyzers in diesel truck repair shops and authorized smog inspection stations where vehicles are tested for emissions purposes. These exhaust gas analyzers tend to measure CO, CO₂, O₂, and NOx.

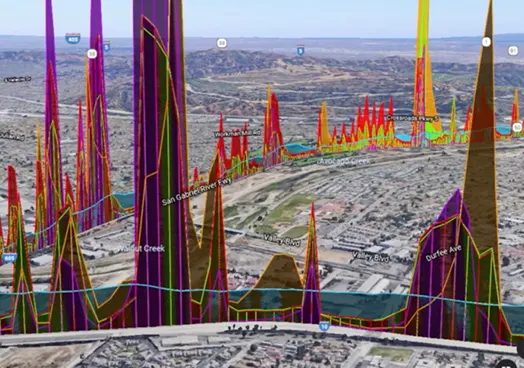

- Portable gas analyzers: are much smaller, cost much less, and deliver the same value as a professional exhaust gas analyzer. The difference is that portable gas analyzers and portable emissions measurement systems (PEMS) can be carried to different locations and can be used for small exhaust engines, motorcycles, forklifts, marine equipment, heavy-duty equipment, and automotive engines. Best of all, they measure all five gases — CO, CO₂, O₂, NOx, and HC — and much more.

- Handheld exhaust gas analyzers: These tend to be the least expensive and are designed to be held in a person’s hands. Handheld gas analyzers can be used on leaf blowers, lawnmowers, and other power tools and measure CO₂, CO₂, HC, and O₂ emissions.

Did you know?

Did you know that gas analyzers aren’t the only way to measure exhaust emissions from internal combustion engine (ICE)-based equipment and vehicles (ICEVs)? Mini, portable emissions measurement systems help companies reduce scope 1, 2, and 3 emissions that can cause air pollution.

With an average internal combustion engine (ICE)-powered vehicle (ICEV) and battery-powered electric vehicle (BEV) producing a combined record 72 metric tons of carbon dioxide over a 15-year life span, smarter gas analysis solutions have never been more important.

Learn more about reducing scope 1, 2, and 3 carbon and greenhouse gas emissions on our Twitter/X page here.

GlobalMRV: The world’s most reliable portable gas analyzers for emissions testing

The time has come for smarter, more efficient, and rapid emissions testing. And there’s no time like the present to make changes.

For more than 20 years, our engineers, researchers, analysts, and technicians have been researching and implementing some of the world’s fastest, most efficient, and most accurate emissions testing technologies on today’s market.

Since 2018 alone, we’ve collected and analyzed over 3,000 hours of reliable data and helped save OEMs and companies more than $5,000,000 on traditional dynamometer and real driving emissions (RDE) testing for clients of all different industries and niches.

If you’re thinking about more efficient, reliable ways to measure and report your emissions output, don’t hesitate to contact us today for your zero-risk, no-cost consultation for any of our services and products. We look forward to working with you to make our world a greener, cleaner place.