OBD-I and OBD-II: perhaps you’ve heard of these Star-Wars-sounding acronyms at your mechanic. But, onboard diagnostics isn’t about sci-fi.

Did you know that you can take advantage of on-board diagnostic (OBD) tools for your business?

Businesses and OEMS: with the demand for stricter regulations in the field of vehicle and real-driving emissions (RDE) testing for environmental, social, and governance (ESG) reporting, you can use OBD to keep your fleet up-to-speed and in compliance with federal regulations and ever-evolving environmental standards.

As the California Air Review Board (CARB) continues to roll out stricter standards for greenhouse gasses (GHG) and other hydrocarbon emissions, you couldn’t have picked a better time to learn about on-board diagnostics and vehicle telematics.

We’re GlobalMRV, the industry’s leading authority on emissions monitoring and verification. Given that the demand for more reliable, accurate, and efficient emissions control and OBD solutions is projected to rise 3.42% over the next five years, we’ve pivoted to meet the industry’s need for smarter diagnostics reporting.

If you’re looking to learn more about how OBD can help you with emissions monitoring, control, and reporting, look no further. In this article, we’ll explore what OBD equipment is, different types of OBD equipment, their applications, the benefits of OBDs for vehicle emissions testing, and other frequently asked questions about OBDs.

Defining on-board diagnostics (OBD)

On-board diagnostics (OBD) refers to standards that are designed to decrease emissions. OBD equipment monitors the performance of major engine components to deliver real-time information about the vehicle or engine’s performance.

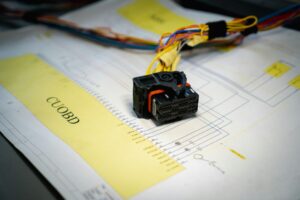

An OBD computer system consists of the following parts:

- Electronic control unit (ECU): this component uses input from various sensors (e.g. an oxygen sensor) to control actuators (e.g. fuel injectors) to reveal information about a vehicle or engine’s performance.

- Sensors: various sensors exist throughout the vehicle and engine. The sensors transmit information back to the ECU. The sensors share the source and parameters of the information received, so that the ECU can interpret the signals and results received by the sensors.

- Diagnostic trouble code (DTC): if the ECU reads information from the sensors that seem to be out of the normal scope and parameters of the sensors, a DTC code will populate on an OBD scanner. A DTC code is a list of letters and numbers that refer to the source and nature of a problem in the vehicle and/or engine.

- Malfunction indicator light (MIL): more commonly referred to as the “check engine light” in vehicles, the MLI indicates whether a malfunction may soon occur in a vehicle. If the ECU detects a DTC, the ECU will send a message to the vehicle’s or equipment’s dashboard. The dashboard then turns on the corresponding indicator light that signals which part of the vehicle (or equipment) needs troubleshooting. In most cases, if the indicator light turns on and stays on, the problem is minor. If the light flashes, the problem is likely urgent.

- Diagnostic link connector (DLC): the DLC is a small port, generally located on the driver’s side of a vehicle. An OBD scanner is then hooked up using a cable to a link connector to help read the diagnostics from the OBD equipment.

While the parts of an OBD system serve a different purpose, the OBD’s central function is quite simple. You can think of an OBD system as a central computer system with a network of sensors and a connection point to help monitor your vehicle and equipment’s performance.

In the next section, we’ll take a look at the different types of OBD equipment that are available in today’s market. You can use OBD equipment for monitoring, measuring, and verifying the emissions of your team’s assets.

Types of onboard diagnostics (OBD) equipment

Over the last 50+ years, two types of on-board diagnostics (OBD) equipment and standards have been used. The two types of OBD on the market include:

- Onboard diagnostics I (OBD-I)

- Onboard diagnostics II (OBD-II)

Let’s explore each in greater detail.

All about OBD-I

The first OBD systems and standards — affectionately named OBD-I — arrived before 1990. Before the ‘90s, each OBD system differed between manufacturers. Codes, systems, and information gathered by each OBD system varied from manufacturer to manufacturer.

While OBD-I equipment provided useful information for engine calibration teams looking to mitigate the impact of carbon emissions, OBD-I systems were complex. With OBD-I systems, researchers, technicians, and product development teams had to purchase new tools and cables for every vehicle make and OBD scanner.

The result? Many users were forced to go to dealership technicians to diagnose issues.

Luckily, the days of having a separate adapter cable and scanner for each vehicle are over. Better yet, technicians and teams can collect valuable information from almost anywhere.

With the invention of portable emissions measurement systems (PEMS), teams can now track their emissions output from almost anywhere — no dealership or facility needed.

The days of OBD-I are over. PEMS and OBD-II are here to stay.

All about OBD-II

In 1994, the California Air Review Board (CARB) issued new OBD standards for OBD systems for all vehicles sold in California. These new standards evolved into OBD-II.

The standards released by CARB for California stated that all motor vehicles were required to come equipped with on-board diagnostic systems.

OBD-II standards specify new requirements, specifically the need for the following:

- An OBD-II connector: a standardized diagnostic link connector (DLC) cable that can be used across a variety of vehicles. These connectors are called type 2 connectors. Via a port located in the vehicle, the cables can access digital communications stored in the OBD system.

- Emissions monitoring: With OBD-II, the Environmental Protection Agency (EPA) required that OBD systems also help monitor problems that can arise as a result of vehicle emissions output.

OBD-II standards allowed for standardized tools to measure the emissions of all vehicles. Because of OBD-II — whether you own a gas, electric, or hydrogen-powered vehicle — you no longer need to buy manufacturer-specific tools to gather quick and reliable data about your vehicle and equipment’s performance.

Common applications of OBD-I and OBD-II

Onboard diagnostic (OBD) equipment is often used to assess issues across a variety of vehicles. Fleet managers, businesses, research and development teams, academics, and OEMs often use OBD to:

- Conduct emissions testing

- Monitor driver behavior

- Test the efficiency and output of other instruments

- Gather commercial vehicle telematics data

Depending on your vehicle, equipment, and needs, OBD may be able to support your next emissions-testing-related venture.

Did you know?

Smog is a combination of nitrogen oxides, particulate matter, and other gasses. But did you know that vehicles that were made in 1996 or later use OBD II scanners for smog checks?

With OBD-II computer systems, you can ensure more reliable smog checks and greater confidence in your efforts to reduce carbon emissions.

Table: 40 years of OBD history

| Year | Key Milestone |

| 1. 1968 2. 1979 3. 1991 4. 1994 5. 1996 6. 2001-2008 | 1. Volkswagen introduces one of the first OBD computer systems. 2. The Society of Automotive Engineers (SAE) recommends a standardized diagnostic device. California requires all vehicles to have onboard diagnostics available. 3. The push to standardize onboard diagnostics comes to be known as OBD-I. 4. OBD-II standards are implemented in response to the need for new standards with OBD-I. CARB also issues OBD-II as a set of standards for vehicles sold in California. 5. For vehicles built in 1996 and onwards, the EPA makes the implementation of OBD-II mandatory. 6. After passing the Clean Air Act, the EPA further expands OBD-II standards in the U.S. The European Union implements EOBD, the European version of OBD. |

Unleash the power of OBD and emissions testing

OBD testing can help businesses and their partners speed up product development, stay in compliance with federal authorities, and gain valuable insights into the impact their equipment makes on the climate.

What’s more, OBD-II provides:

- Quick diagnoses (with detailed diagnostic trouble code (DTC) systems through standards set in SAE J1939)

- Accurate information (and reduced errors)

- Detailed metrics (to monitor engine performance, driver behavior, and more)

- Better compliance (with adhering to the Environmental Protection Agency’s (EPA) standards)

With GlobalMRV, we can help you test all different types of vehicles, equipment, and heavy-duty machinery. Whether you’re testing the exhaust output of a single electric motorcycle or a fleet of maritime vessels, our team of PhD researchers, engineers, analysts, managers, and technicians can provide reliable and accurate emissions data for you and your entire team.

In the last six years alone, we’ve collected and analyzed over 3,000 hours of reliable data and helped save OEMs and companies more than $5,000,000 on traditional dynamometer and real driving emissions (RDE) testing for clients of all different industries and niches.

To learn more about the synergy of OBD-II and portable emissions measurement systems (PEMS), don’t hesitate to contact us today. We’d be happy to help you with all your vehicle and equipment needs!

Frequently asked questions (FAQ) about onboard diagnostics

Where can I find the OBD-II port on my vehicle?

On most vehicles built after 1996, the OBD port can be found on the driver’s side of the vehicle and underneath the dashboard. The port may have a 16, 9, or 6-pin configuration.

We also recommend checking your owner’s manual for more specific information on where the OBD port resides.

How do OBD-I and OBD-II systems differ?

OBD-I systems connect to a console outside of the car. With OBD-II, the computer system is integrated within the car.

Other than the configuration, OBD-II systems also offer expanded capabilities.

What types of data do OBD-II systems collect?

OBD-II systems can collect data, such as (but not limited to):

- Engine revolutions

- Vehicle speed

- Fault codes

- Fuel usage

- Emissions readiness

- Oxygen sensor-related information

Can I rent emissions equipment that includes OBD-II sensors?

Yes! An OBD-II scanner can be rented. These test devices are often to measure, monitor, verify, and report on the emissions output of your vehicle and/or equipment.

If you’re not keen on purchasing equipment, you can also always opt to rent equipment with part of our hardware as a service (HaaS) package.

At GlobalMRV, we offer HaaS on all of our portable emissions measurement systems (PEMS) and accessories. To lease your PEMS product with HaaS, contact us today!

Another essential reason to switch to solar power is the financial savings it provides. Solar panel systems can handle generating electricity for businesses, reducing or eliminating the necessity for traditional types of energy. This may lead to significant savings on energy bills, particularly in areas with a high energy costs. Furthermore, there are many government incentives and tax credits open to companies that adopt solar technology, rendering it a lot more cost-effective and affordable.

The technology behind solar technology is simple and easy, yet highly effective. Solar panel systems are made of photovoltaic (PV) cells, which convert sunlight into electricity. This electricity can then be kept in batteries or fed straight into the electrical grid, with respect to the specific system design. So that you can maximize some great benefits of solar technology, you will need to design a custom system this is certainly tailored to your particular energy needs and requirements. This can make sure that you have just the right components set up, like the appropriate quantity of solar energy panels together with right form of batteries, to maximise your time efficiency and value savings.

Good day! Your website is a valuable resource.